------ WHAT YOU CAN BENEFIT FROM RT SERIES SYSTEMS ------

YOU CAN PRODUCE SODIUM HYPOCHLORITE

ON-SITE AND ON DEMAND AND DISINFECT USING THIS SYSTEMS

&

AVOID HANDLING TOXIC CHLORINE

With Safe, Effective and Healthy Disinfection System

Which is Easy to Handle And Operate

and the Compact Modular Design Requires Less Space

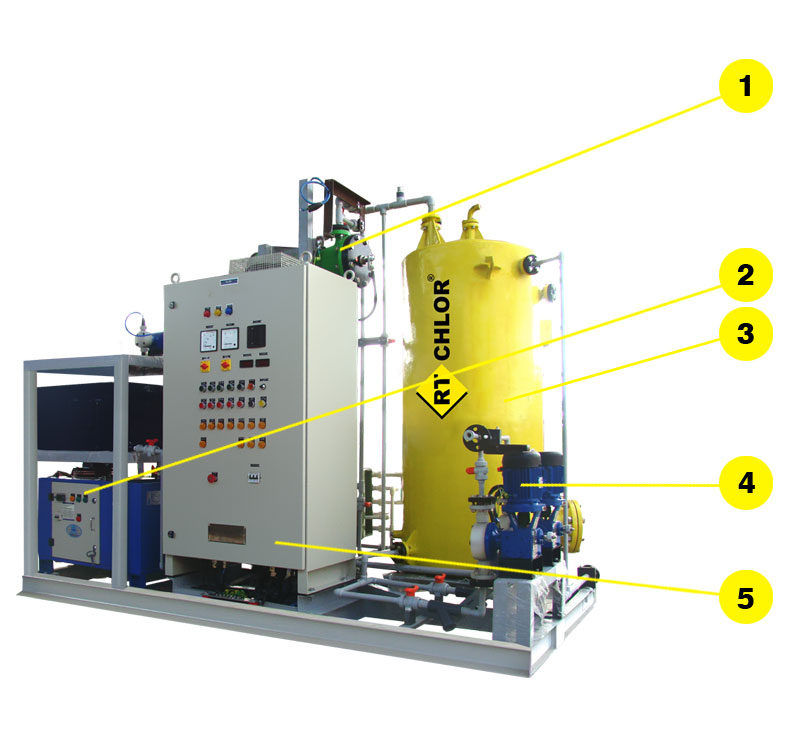

TYPICAL HYPOCHLORITE SKID

APPLICATIONS

- Municipalities & corporation water disinfection

- Waterboards, townships water treatment

- Theme parks , swimming pool treatment

- schools, colleges,hotels & hospitals

- recreation centers, restaurants waste water

- residential apartments / colonies water

- chemicals & fertilizer industry disinfect water

- petrochemicals, mining & refineries water

- cement, steel,sugar & bottling plants

- textile,tanneries, pulp & paper industries

- power generation & power utilities water

- Pharmaceutical industry water disinfection

RT CHLOR® BRINE SYSTEM

Onsite Hypochlorite Generation using Brine or Common Salt

Noble Eco Systems's state of art RT CHLOR® SERIES hypochlorite generation systems / electrochlorinator is result of more than 3 DECADES of experience in design & manufacturing electrolyser for various electrochemical applications.

A simple and proven process technology to convert ordinary salt (common salt), by means of electrolysis into 1st grade sodium hypochlorite (ELECTRO HYPO) using RT CHLOR® SERIES hypochlorite generators ( electro chlorinator system). It is always applied on-site, at the Point of Application. No chemicals other than ordinary salt is used throughout the process. A diluted brine solution is fed through an electrolyser cell ( chlorinator ). When a low voltage DC current is applied, electrolysis occurs and sodium hypo chlorite (NaOCl) is generated instantaneously. HYPOCHLORITE is generated electro-chemically between 0.2% and 0.8% depending on the application. The only by-product hydrogen is safely vented into the atmosphere.

Noble Eco Systems’s onsite hypochlorite systems are automated chlorinator packages, single cell standard unit or packages & modular based large capacity units and can be supplied as skid mount or containerized, fully integrated package or as loose components. Noble Eco Systems guarantees a high level of performance for every units and ensures rapid response to emergency repairs and recoating cells, upgrading to new technology and integrating current systems with custom built modifications.

Our Services

- System Revamping

- Spares Refurbishment

- Replacement

- AMC