BEFORE

BEFORE

MONOPOLAR CELL

We refurbish the complete monopolar electrode (anode+cathode) assembly and re-fit with new coating of anodes and replace the etched fins or tubes with new spares and hardwares.

BEFORE

BEFORE

MONOPOLAR CELL CATHODE

Cathode assemblies are welded and etched / damaged fins are replaced with new plates.

BEFORE

BEFORE

BIPOLAR CELL

Bipolar cells are repaired by removing scales and damaged anode plates and re-coating end-anode assemblies

BEFORE

BEFORE

END ANODE ASSEMBLY

We repair the end-anode assembly and re-coat after welding titanium assembly in clean rooms; then we assemble & integrate it with the electrode assembly to finish the electrolyser manufacturing process.

BEFORE

BEFORE

ELECTROLYZER HOUSING

We do cleaning of electrolyser housing and are capable of repairing and fabricating new cell housing from our FRP fabrication division.

BEFORE

BEFORE

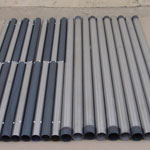

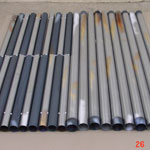

TUBULAR ELECTROLYSER

Titanium tubes are scale removed and the half-cell anodes are re-coated with Mixed metal oxide Coating (ATMA®)